20 Lanes Automatic Wet Wipe Making Machine for Baby Wipes Wet Towel Tissue Manufacturing Packing Production Line

YY-DP-20 20 Lanes Automatic Wet Wipe Making Machine For Baby Wipes Wet Towel Tissue Manufacturing Packing Production Lin

Description

Basic Info.

| Model NO. | YY-WPZ-20 |

| Condition | New |

| Control | Automatic |

| Embossing Type | Special Folding Unit |

| Embossing Roller | Wet Wipes Packing |

| Tissue Packaging | Bag |

| Function | Packaging |

| Tissue Type | Wet Tissue |

| Core Components | PLC, Engine, Motor |

| Materials | Stainless Steel |

| Power | 20kw |

| Weight | 15000kg |

| Function 1 | Folding-Wetting-Cutting-Counting-Packing |

| Feature | High Speed, Good Performance and High Stability |

| After Warranty Service | Video Technical Support |

| Application | Wet Wipe Industry |

| Product Name | Wet Wipes Production Line |

| Wetting System | Automatic Wetting Liquid |

| Transport Package | Wooden Case or in Seaworthy Package |

| Specification | 20000x3600x2300mm (LxWxH) |

| Trademark | YiYi |

| Origin | Quanzhou China |

| HS Code | 8441809000 |

| Production Capacity | 50 Sets / Year |

Product Description

YY-DP-20 20 Lanes Automatic Wet Wipe Making Machine For Baby Wipes Wet Towel Tissue Manufacturing Packing Production Line(1)Technical parameters:

| Product type | Baby wipes, dress up wipes, lady wipes, cleaning wipes |

| Product speed | 400-500cuts/min |

| Suitable materials | Spunlace non woven; Hot-rolled fabric |

| GSM | 40 - 80g/m2 |

| Working voltage | 380V 50HZ |

| Power | 20KW |

| Raw material width(mm) | 1000-1320 |

| Slitting line | 6,12,16,20 lines |

| Unfolded size(mm) | (120-300)×(150-300)(L×W) |

| Folded size (mm) | (120-300)×(90-120)(L×W) |

| Folded type | "Z","C""N" Pop up or Non-Pop up(adjustable) |

| Counting mode | Counting automatically,automatic adjustable stacking system |

| Wetting system | Double tanks with agitators |

(2) Main features:

1- Drive mode:Adopted step motor , Servo motor and frequency conversion combination.Main drive shaft adopted couple jointer.Rear driving by time belt and time wheel.Adopted widen time belt for high tension suffered parts.

2- Control system:Delta PLC control system.Auto control function.

3- Operation mode: adopted operating interface. To press the programmable menu for every operation. Every dates can be easily adjusted, recorded and seek. Auto checking for product convey, when any of the raw materials lacking or breaking off, the machine can be shut off automatically at the shortest time to decrease the defective.Product conveying: Adopted imported convey belt driven. The friction coefficient can be auto profit adjusted at low or high speed to ensure whole line in consistent situation.

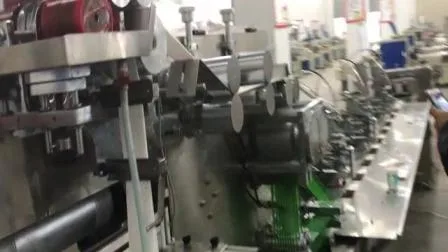

(3) Product photos:

FAQ:

Q1:Are you a factory or a trading company?A1:We are the manufacturer and factory, specialized in wet wipes machinery,packaging machinery industry since 2010.Q2:Where is your factory? How can I get there?A2:Our factory is located in Nanan City, Quanzhou City, Fujian Province, China.our nearest airport is JIN JIANG airport, if you take plane, it will need about 1 hours from Guangzhou,1.5hours from shanghai and 2 hours from Beijing. We will pick you up from airport as well as the train station. Welcome you and your team to visit our factory.Q3:What's your main market?A3:Our machines are sold well in 30 provinces and cities and enjoy high reputation in China. Also,it has been widely exported to more than 60 countries, such as Korea, India, Bangladesh, Russia, Pakistan, Brazil, USA, U.A.E, Kazakhstan,South Africa etc.Q4:How is your factory doing in quality control?A4:Quality is the most important principle. There are at least twice test before shipment, the first is by our factory, the second is together with customer. And also we will offer whole-life service. What's more, all machinery has been passed CE testing. Strictly testing the machine and arranging delivery after 100% confirmation of no problem are what we always do.Q5:How about after sales service?A5:The machines arrive at buyer's plant and everything is ready for testing (including raw material ,electric, air and relative project) ,seller will send 1 engineer /technician to buyer's plant, buyer should pay for all relative expenses which occur because of it (such as return tickets, local travelling fee, the cost of accommodation, food and technicians' salary USD100/day/person.) 2- Online technical guidance, operation video provided.

Prev: High Speed Automatic CE Wet Wipes Tissue Packing Packaging Machine

Next: Napkin Packing Machine Single Wet Wipe Packaging Machine

Our Contact

Send now